The details are as follows:Ĭ omponent layout: It may limit your panelization options in the placement of components and connectors, where particularly those hanging off the edge of a PCB. There are some factors you need to take into consideration if you want to get the benefits of mass production that come with panelization. Alternatively increasing the width to fit on the assembly line with a PCB processing edge around an individual PCB. And it’s easy for each board to depanelize or remove from the array so that packaging or installing into the product. PCB panelization is a fabrication technique, which makes it easy to pass through the assembly line because the smaller PCBs are fabricated and connected together as a single array. And how it can help you with your manufacturing needs. Now PCBGOGO will explain what is PCB panelization. What’s more, it is not only cost-effective, but also can help your PCB manufacturing. Another important layout specification, which is board edge clearance, determining your PCB panelization for manufacturing and assembly. These specifications and spacing determine whether your layout can be manufactured. PCB layout, which may be the most important aspect of PCB design, it defines the traces and drilling, as well as where the components will be mounted. Rayming is China PCBA Manufacturing factory that do PCB and PCB assembly China on one-floor to provide quick turn ,easily quality control service to electronic industry.

Standard PCB have no parts on the top and are often referred to as “Printed Wiring Boards (PWB).” Thus, the finished board of printed circuit or printed circuit is called printed circuit board, also known as printed board or printed circuit board.

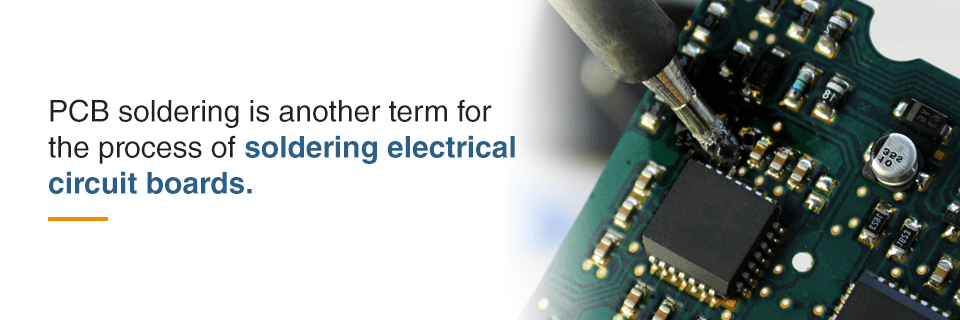

A conductive pattern that provides an electrical connection between components on an insulating substrate is referred to as a printed circuit. Generally, a conductive pattern formed on a conductive material according to a predetermined design to form a printed circuit, a printed component, or a combination of the two is called a printed circuit. PCB (Printed Circuit Board) is an abbreviation for printed circuit board. That is to say, the PCB Bare board passes through the SMT patch, and then passes through the entire process of the DIP plug-in, referred to as PCBA. PCBA may be understood as a finished circuit board, and the PCBA can be made only after the process on the circuit board is completed. Chip components such as chips are attached to the PCB. PCB(Printed Circuit Board),Made of epoxy glass resin material, it is divided into 4, 6 and 8 layers according to the number of signal layers. PCB refers to the circuit board, while PCBA refers to the circuit board plug-in assembly, SMT process. One is a finished board and the other is a bare board. What is the difference between PCB and PCBA?

0 kommentar(er)

0 kommentar(er)